The importance of make ready engineering

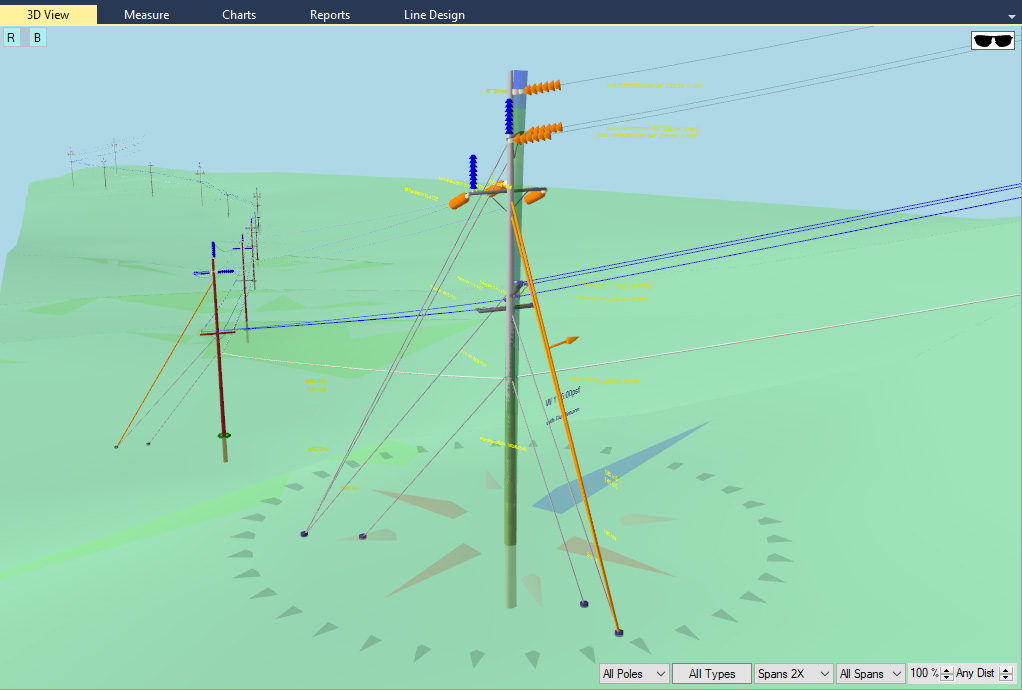

Utility work often goes underappreciated, despite its crucial role in establishing the infrastructure that keeps us connected. This essential work enables the delivery of internet, telephone, and television services to communities globally. At PoleFiber, we specialize in Make Ready Engineering (MRE), ensuring that utility poles are properly prepared to receive new attachments, typically fiber optic cables.

Our process involves collaboration with various stakeholders, such as pole owners and telecom providers, which can complicate coordination as projects expand. Additionally, our work must adhere to National Electrical Safety Code (NESC) guidelines. Fortunately, PoleFiber brings years of expertise in the utility sector, combining consistent communication with deep project understanding to ensure timely completion of these challenging projects.

Communication challenges

One of the most significant hurdles in MRE stems from communication issues. While joint-use utility poles maximize efficiency by housing attachments from multiple entities, they often introduce delays and complexity. Poles are typically owned by governments or companies in the electric or telecom sectors, and their capacity must be meticulously tracked to accommodate new requests. Miscommunication or lack of key information between stakeholders can disrupt project timelines.

At PoleFiber, we prioritize collaboration and establish correct points of contact early in the process to minimize delays. By simplifying workflows and gathering comprehensive data ahead of fielding efforts, we ensure that critical information isn’t overlooked. Reaching the right individuals also ensures compliance with NESC standards and permits projects to proceed smoothly. With extensive experience managing joint-use projects, our team is adept at tailoring solutions to each project’s unique needs. For us, communication isn’t just about sharing data, it’s about transforming information into actionable steps that deliver results.

Navigating standards

Utility work evolves alongside technological advancements, and staying up-to-date on regulations is essential for successful project execution. Published every five years by the Institute of Electrical and Electronics Engineers (IEEE), the NESC establishes safety standards to protect utility workers, the public, and property while minimizing liability for pole owners. While local pole owners can impose additional restrictions, these must comply with NESC guidelines. Operating across diverse markets often introduces variations in regulatory requirements, but proactive communication makes navigating these complexities more manageable.

PoleFiber’s adherence to codes and standards reflects our commitment to safety and reliability. We proactively identify overloaded poles or potential code violations during inspections and notify owners promptly. By ensuring full compliance with regulations, we help stakeholders mitigate risks and maintain stability throughout their systems.

Managing overloaded poles and violations

Overloaded poles pose unique challenges that require careful evaluation and strategic resolution. Depending on project needs, solutions may involve replacing poles entirely or burying cables – a decision often influenced by terrain, pole spacing, and attachment type. While underground utilities can be cost-intensive, PoleFiber’s professionals leverage 15 years of industry experience to recommend the most efficient options for clients. If an active or potential violation exists, we alert owners immediately, reducing long-term risks and supporting informed decision-making. Ultimately, PoleFiber’s make ready engineering services are designed to streamline complex utility projects with clear communication, regulatory expertise, and practical solutions. By addressing these challenges head-on, we ensure that communities stay connected without compromising safety, efficiency, or reliability.

Fielding

Fielding plays a critical role in our MRE operations. To effectively gather pole data, our field technicians utilize a diverse set of tools, including an extendable height stick, pen tablet, compass, laser meter, and digital camera, among others. These tools, particularly the tablet, enhance our versatility and efficiency when working on-site. Additionally, PoleFiber technicians inspect the surrounding area to identify any inconsistencies or overlooked details in the initial plan.

Once the data collected through these tools is documented and the pole specifications are recorded, it is forwarded to the office for further processing. The data undergoes several specialized types of analysis, such as structural evaluation, space planning, midspan clearance assessment, and pole load analysis. These processes ensure that measurements are accurate and compliant with NESC standards, as well as those of the pole owner. Following these analyses, our reports are reviewed, stamped, and delivered to the relevant stakeholders. To uphold safety standards and client satisfaction, we also conduct post-inspections once work is completed.

Engineering presents its own set of challenges, but with PoleFiber extensive expertise and experience, we simplify the MRE process for clients and partners.